Products

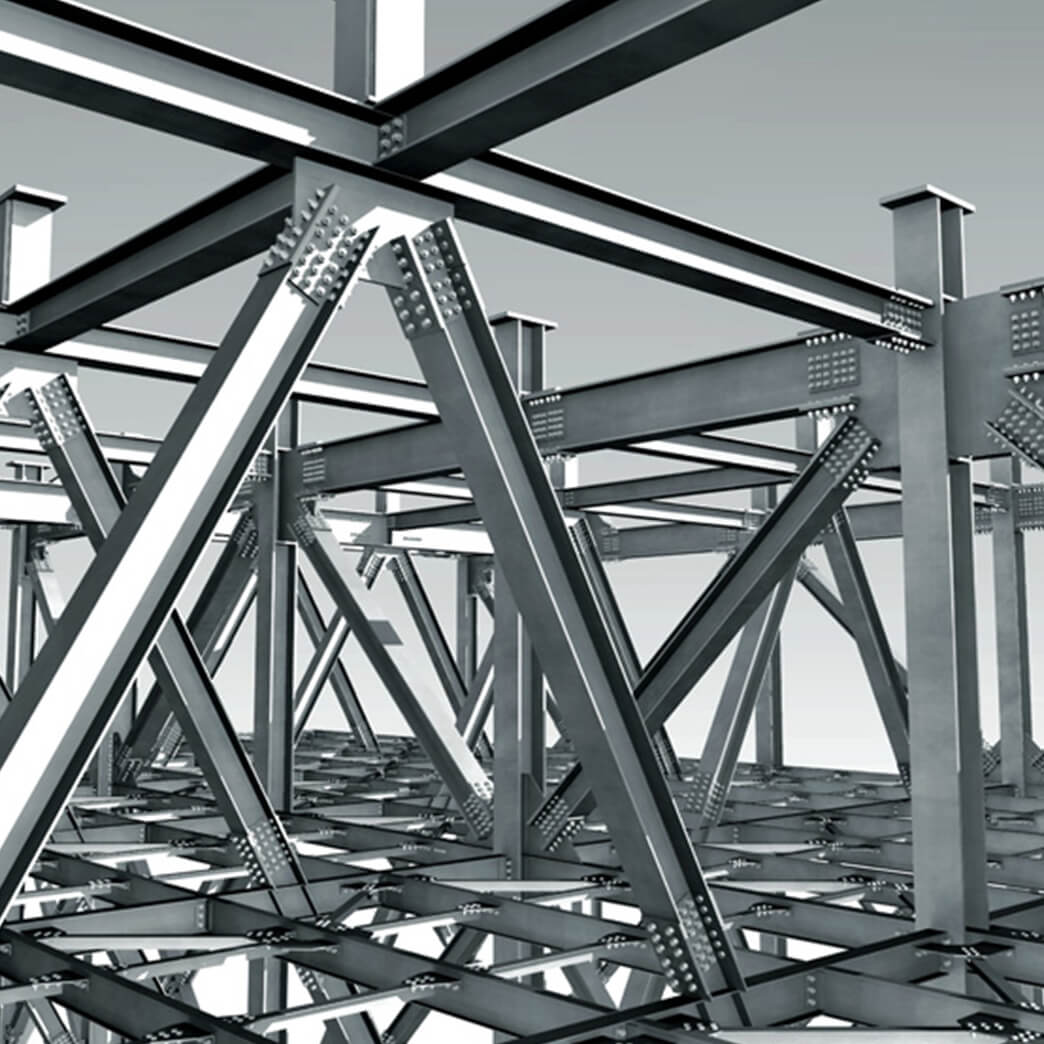

Steel Structure

Steel Structures’ Fabrication & Erection

The process of steel fabrication in IPIC involves grinding, welding, cutting, bending, drilling, punching, burning or melting and other general crafting methods using various high-quality tools and CNC equipment. The entire steel fabrication process is systematic and requires utmost planning, precision, and knowledge. Steel fabricators are well aware of all the crucial steps and measures that need to be considered in the fabrication process. Structural steel is usually fabricated to create structures like beams, trusses, hollow sections, angles and plates.

These steel members must be accurately fabricated before assembling them together. All component parts of these members are fitted-up temporarily with rivets, bolts, or small amounts of welds. Various fastening methods are employed to deliver different types of finishes. Finishing is generally performed by milling, sawing or other suitable methods.

It’s important to understand how steel structures are designed before assembling them together.

Construction Needs:

First and foremost

IPIC has a professional technical engineering specialists empowered with latest technologies and most efficient devices to provide all required engineering works such as design, workshop drawings, planning, monitoring and controlling of all production stages.

It’s crucial to know the type of structure you want to construct. Commercial structures have a distinct designing process. Similarly, residential structures are totally dissimilar from industrial structures. Hence, all the structures demand different types of construction processes. Moreover, any type of construction process requires unique structures varying in sizes, dimensions, and designs. Each structure has to be specifically designed and fabricated before constructing and assembling them together. For any joint to be site welded, the members will have to be held securely in position such that the setup for welding is accurate and rigid.

Steel Erection:

There are four primary tasks that need to be considered before the steel erection process.

- It is extremely important to establish the foundations and confirm if they are suitable and safe for erection to commence.

- With the help of cranes or sometimes by jacking, lifting and placing components into position is essential. Additionally, to secure the components in place, bolted connections are made but they may not be fully tightened. Similarly, bracings may not be fully secured.

- Aligning the structure is essential, principally by checking that column bases are lined and leveled and columns are plumb. To allow column plumb to be adjusted, packing in beam-to-column connections may need to be changed.

- Last but the least, bolting-up is required, which means completing all the bolted connections to secure and impart rigidity.

Steel fabrication and erecting steel structures are a lengthy process and they require immense skills, knowledge, and practice. Our steel fabricators at IPIC use the best steel fabrication tools and equipment to ensure that the fabrication and erection processes of steel structures are done with accuracy and perfection.

Erection Techniques:

Mobile man boom lift (MMBL) and cranes are predominantly used in the erection of steel structures for buildings and bridges. However, there are other various techniques that are sometimes used for constructing steel bridges. Cranes are usually divided into two broad categories, mobile and non-mobile cranes. Truck mounted, crawler and all-terrain cranes are included in the first category, while tower cranes are included in the second category.

The MMBLs can be used both on the ground or on the partly erected steel structure, in order to erect lighter steel elements. These MMBLs are used to access the steelwork during erection to bolt up the pieces lifted by the crane. Important measures need to be taken before using the MMBLs such as first checking if the steel structure can support the weight of the MMBL and then determining whether they should be used on the ground or on the erected structures.