Products

Hot Induction Bends

SPECIFICATIONS

| Diameter | 4" to 48" |

|---|---|

| Thickness | 7.9 : 38.1 mm |

| Bending Angle | Any Degree up to 180° |

| Minimum Bend Radius | 3DR |

| Material | In compliance with API 5L up to grade X-80 or equivalent |

Manufacturing Process

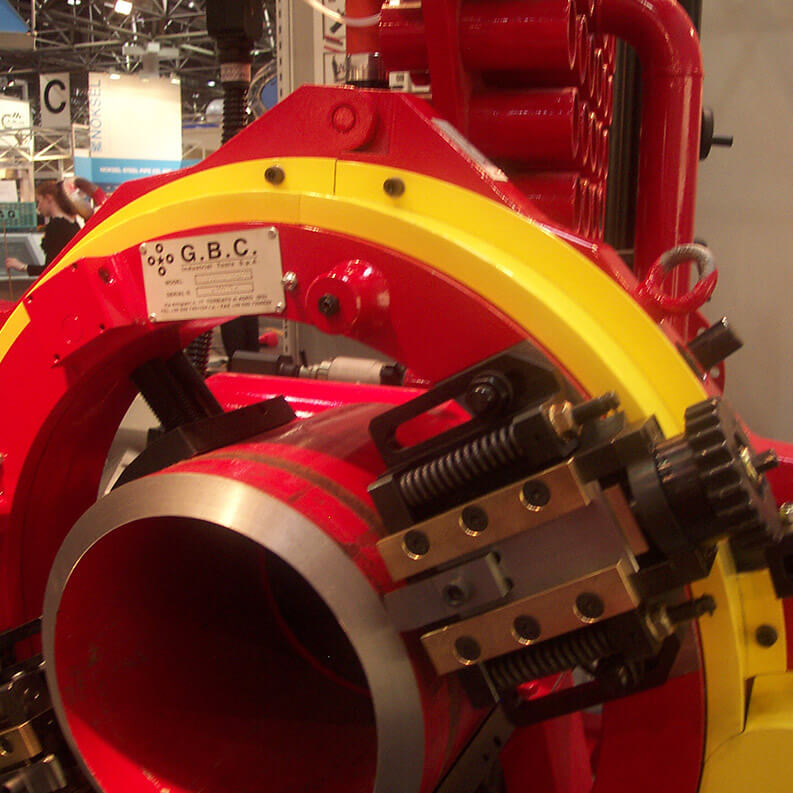

Induction Bending M/C

The machine used the induction bending theory to convert the straight pipe into bend. The powerful design of the machine allows producing of 3d induction bends and any angle up to 180 degree.

Dimensions Check

Visual and dimensions check performed on bend before and after heat treatment in order to assure and guarantee the required dimensions.

Heat Treatment

Depending on the requested mechanical properties, The bend may be heat treated after bending in order to achieve the aimed mechanical properties.

Hydrostatic Test

According to client requirement and the bend usage, hydrostatic test may be carried out on all bends or sample bend for qualificaton.

End Beveling M/C

For bends ends preparation, to the required angle and root face according to the project specifications.

Inspection

Visual and dimensional check performed on each bend, the inspection stages include but not limited to bend ovality measurement, ut on seam weld and bends’ ends test for lamination.